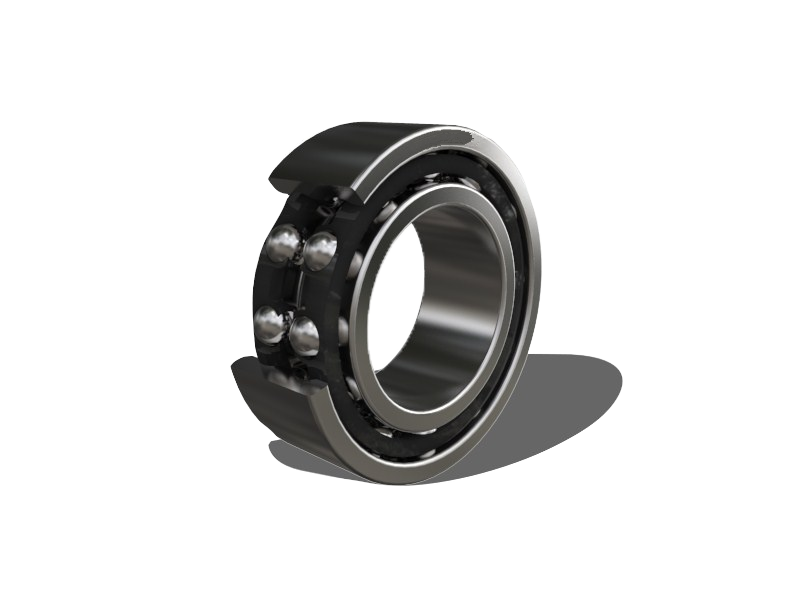

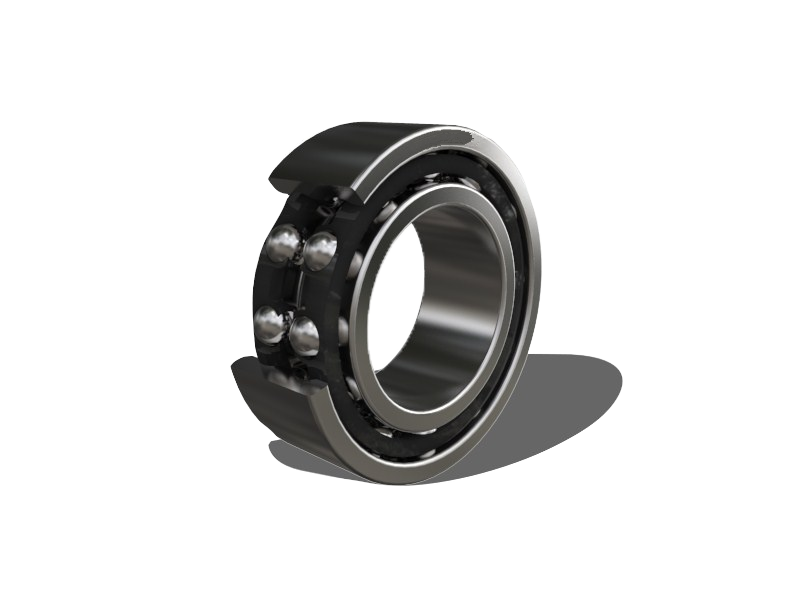

Simple cleaning and lubricating method for textile sealed bearings

New cotton spinning equipment uses a large number of sealed bearings due to the requirements of dustproof, heatproof and high speed. After a certain period of operation, these bearings are damaged due to dry grinding of the bearings due to the lack of oil inside. For example, the number of sealed bearings on imported air spinning machines is large and the material is good. However, after several years of use, the sealed bearings cannot be cleaned or replenished with grease, which results in a large number of damaged and discarded sealed bearings, which increases equipment failure and unnecessary expenses.

DAC shares Two simple and effective cleaning and refueling methods:

If these bearings can be cleaned and refueled regularly, they will prolong their service life, save a lot of money and reduce the occurrence of bad cars.

The first sleeve cleaning and oiling method is suitable for sealed bearings with gaps at both ends of the bearing housing. The method is to immerse the bearing in kerosene for 1 h to 2 h, and then make a special sleeve according to the outer diameter of the bearing, which can be cleaned and refueled. The inner diameter of the sleeve is slightly larger than the outer diameter of the bearing from 0.05 mm to 0.08 mm, which is slightly shallower than the bearing. Cleaning and refueling steps: add appropriate amount of kerosene into the sleeve, press the bearing in by hand, use the clearance of the bearing itself to squeeze out the kerosene, repeat 1 or 2 times; after cleaning and draining, add the required grease into the sleeve The bearing is placed in the sleeve and pressed down gently with a pressure device. The amount of oil to be added to the bearing can be flexibly controlled according to requirements.

The second type is suitable for special fully enclosed bearings, which have a gap at one end and a positioning screw hole. Use the positioning screw hole to communicate with the bearing gap, soak the bearing in kerosene for 1 h to 2 h, suck in the kerosene with a special grease nipple and oil gun, and repeatedly hit the bearing for 2 to 3 times. After drying, use the oil gun to lubricate the required Just add the fat.

Get more information bout DAC here.