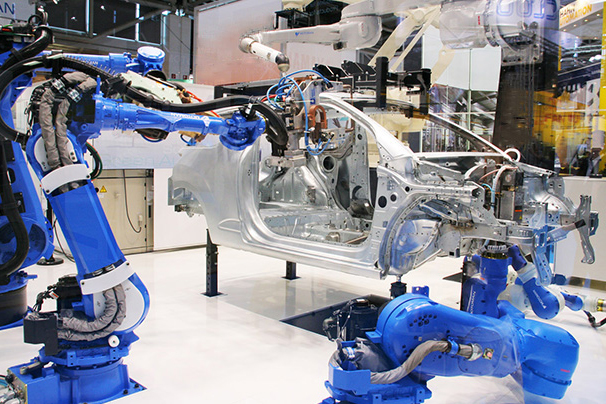

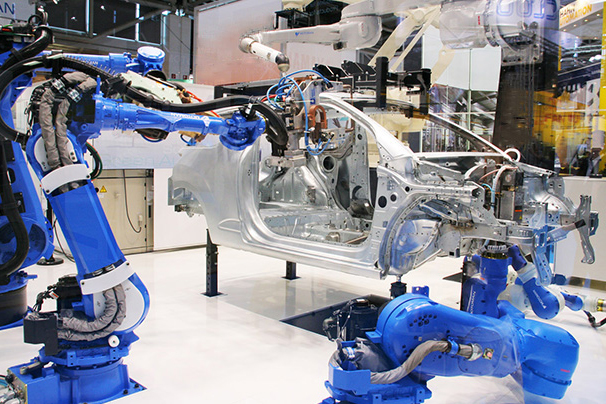

The use of robotics and automation continues to grow more prevalent across industries, particularly in manufacturing, as companies are realizing the full potential of its ability to reduce costs, boost production and deliver greater efficiency and competitiveness.

Typical industrial robotic applications include welding, painting, assembly, product inspection and testing. As the technology has progressed, automation has demonstrated exponential improvements in endurance, speed and precision, with more sensitive applications in medical and other high-tech sectors becoming common.

With highly choreographed, programmed movement on two or more axes, bearings play a major role in the motion control aspect of this technology. The use of high-precision bearings are an integral consideration for those tasked with designing and maintaining these applications. Bearing life and performance demand that the correct type, material and lubrication are specified.

Single-row deep groove ball bearings, with sizes ranging from miniature to extra-large, are generally the go-to bearing choice for the majority of robotic and automation applications. Thin section bearings are often designed into robot arm joints due to their low mass, space-saving construction and high-speed capability.

Roller bearings are usually the first choice for heavy-duty requirements. Slewing rings are a common selection for the main rotation and associated lift equipment. Hybrid (ceramic balls with stainless steel rings) and full-ceramic bearings are an excellent alternative for operation in a vacuum or other inhospitable environments.

The hazardous environments to which robotic applications are often subjected demand proper contamination protection in order to prevent debris of all types, shapes and sizes from entering the bearing and causing irreparable damage or premature failure.

There are many bearing closure types available, each with their own set of advantages. Regardless of the style, closures extend bearing life by preventing contaminants from reaching critical surfaces inside the bearing and help retain lubricant in the bearing.

Metallic shields make no direct contact with the inner ring, which minimizes rotational torque and helps maximize operating speed. Molded rubber seals (typically made from trusted Buna-N material) make contact with the inner ring, which provides better protection in more contaminated environments compared to metal shields, but would also increase startup and running torque due to seal resistance.

Seals might also decrease maximum rotational speed against desired rpm level, which must be taken into consideration. Depending on the bearing type, combination style seals/shields may be available for extra protection.

With excellent resistance against exposure to certain chemicals, glass reinforced PTFE seals may be a preferred choice, as it also allows higher running speed and less torque resistance compared to rubber seals.

The operating environment, applied load and intended motion profile may also influence the selected bearing material. For harsh or corrosive environments, typical in medical, food service and chemical processing applications, 440C stainless steel is often specified for the rings and balls instead of standard hard chrome steel material.

Proper bearing lubrication is another important consideration in optimizing performance and extending the life of the bearing. For example, in food and beverage processing environments, strict regulatory guidelines often dictate the use of H1 food-grade lubricants – which typically have synthetic, hydrocarbon base oils with urea, polyurea or aluminum complex thickeners – due to the possibility of incidental contact.

The critical functions of the lubricant is to minimize frictional resistance and wear of the moving parts, which are (in the case of bearings) the balls or rollers and the ring raceways. A lubricant that is designed for specific operating conditions will provide a proper load-bearing, wear protective film. The ideal condition maintains separation of these frictional surfaces by this film. Moreover, the lubricant will allow for heat dissipation and overall bearing thermal stability. The proper lubricant selection will avoid rapid deterioration over time as well as offer protection against corrosion, moisture and contaminant ingress.