How do you konw Electrically insulated bearings?

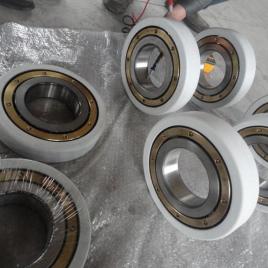

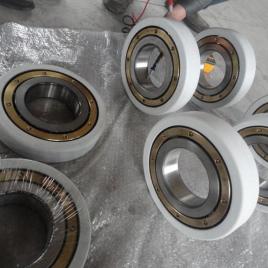

Electrically insulated bearings use a special spraying process, which is coated with a high-quality coating on the outer surface of the bearing. The coating has a strong binding force with the substrate and good insulation performance. It can avoid the galvanic effect of the induced current on the bearing and prevent the current from affecting the grease and rolling elements. , Damage caused by raceway, improve bearing life. This process is constantly being improved. In insulated bearings, there is a layer of 100 μm thick coating on the outer ring or inner ring surface, which can withstand a voltage of up to 1000 V DC. The special spraying process can form a layer with uniform thickness and strong adhesion, and then undergo further treatment to make it not affected by moisture and humidity.

Electrically insulated bearings can avoid damage caused by electrical corrosion, so compared with ordinary bearings used in motors can ensure more reliable operation. Compared with other insulation methods, such as shaft or shell insulation, it is more cost-effective and reliable. The dimensions and basic technical characteristics of insulated bearings are the same as those of non-insulated bearings, so they can be interchanged 100%. It is suitable for motors and generators, especially frequency conversion motors.

DAC is a professional of oil field bearing supplier.

2020-06-30