Common quality defects after heat treatment of composite bearing parts are: overheating of the quenched structure, overheating, quenching cracks, lack of hardness, heat treatment deformation, surface decarburization, soft spots, etc., the microstructure after overheating quenching can be removed from the rough opening Observe the combined bearing parts. But to determine the level of overheating, it is necessary to look at its microstructure. If the quenched structure of GCr15 steel presents coarse acicular martensite, it is a quenched superheated structure.

The reason may be that the quenching heating temperature is too high or the heating and persistence time is too long to cause overheating. Or it may be due to the existence of severe tungsten carbide bands in the original structure, and the low-carbon regions between the two regions constitute part of the martensite needles. Caused by partial overheating. The remaining austenite in the superheated structure increases and the dimensional stability decreases.

Due to the overheating of the quenched structure and the roughness of the steel crystal, the toughness of the parts will be reduced, the impact resistance will be reduced, and the life of the bearing will be shortened. Severe overheating may even cause quenching cracks. Low overheating quenching temperature or poor cooling effect will produce microstructures in the microstructure that exceed the quenched and tempered structure specifications, called overheated structures, which will reduce the hardness and sharply reduce the wear resistance, thereby affecting Bearing.

Quenching cracks The cracks formed by internal stress in the quenching and cooling process of bearing parts are called quenching cracks. The reason for this kind of cracking is: due to high quenching temperature or too fast cooling, the structural stress when the thermal stress and metal volume change is greater than the fracture strength of steel. The original defects on the work surface (such as external microcracks or scratches) or the internal defects of the steel (such as slag inclusion, serious non-metallic inclusions, white spots, shrinkage holes, etc.) constitute stress concentration during the quenching process.

Severe surface decarburization and carbide segregation; after quenching, the parts may not be tempered in time due to insufficient tempering; the cold punching stress formed in the previous process is too large, forging and folding, deep turning tool marks, sharp corners of the oil groove, etc. In short, the cause of quenching cracks may be one or more of the above elements. The existence of internal stress is the main cause of quenching cracks.

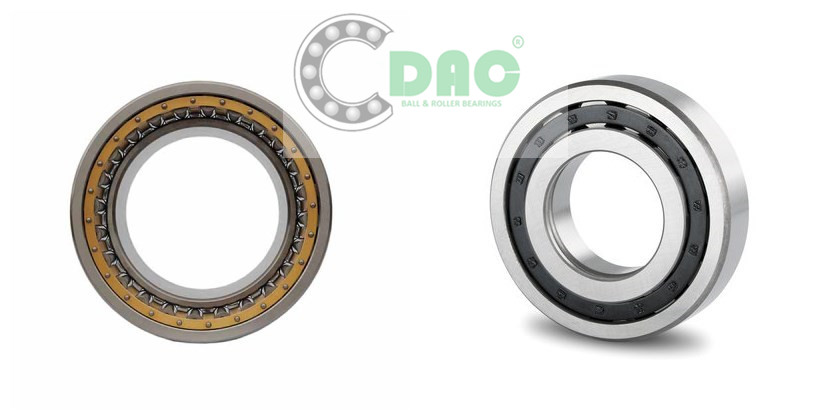

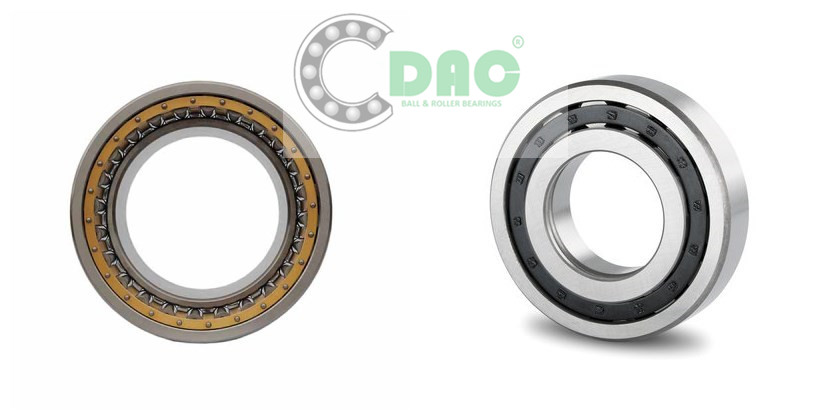

DAC Bearing supplies bearing for Oilfield Machnery,such as cylinderical roller bearing --SL series Bearing,NUTR series of Needle roller bearings, single or double row angular contact ball bearings and eccentric bearing fro special machinery.

Get more information here.

Contact us for detail here.